Machining lines

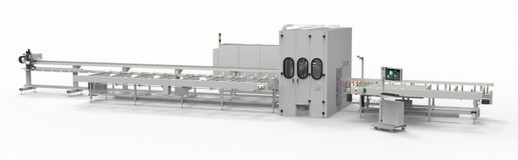

LMX 650

Machining and cutting belt with Ø 650 mm front blade and 300x300 mm bar passage

A max. 18 machining units machined with an electric spindle and an infinite 360 ° rotary cutting unit result in a continuous flow for measuring machined and cut elements. The XMU Auxiliary Machining Module performs end milling (with paddle, milling cutter or milling units), holes and head drilling, as well as 45 ° and 135 ° bevel cuts, guaranteeing maximum flexibility for many applications. There are 6 different versions that can be configured for the length of the material loading / unloading bins and the dosing direction.

A max. 18 machining units machined with an electric spindle and an infinite 360 ° rotary cutting unit result in a continuous flow for measuring machined and cut elements. The XMU Auxiliary Machining Module performs end milling (with paddle, milling cutter or milling units), holes and head drilling, as well as 45 ° and 135 ° bevel cuts, guaranteeing maximum flexibility for many applications. There are 6 different versions that can be configured for the length of the material loading / unloading bins and the dosing direction.

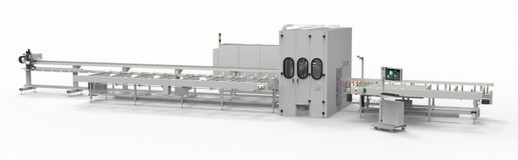

LMT 65

Machining and cutting line with front Ø 650 mm blade and bar passage 250x200 mm

A max. 16 machining units machined with an electric spindle and a cutting unit with a blade inclination controlled from 20 to 160 ° result in a continuous machined and cut flow for measuring the elements. There are 20 different versions that can be configured according to the depth and length of the material loading and unloading bins and the right or left feed direction.

A max. 16 machining units machined with an electric spindle and a cutting unit with a blade inclination controlled from 20 to 160 ° result in a continuous machined and cut flow for measuring the elements. There are 20 different versions that can be configured according to the depth and length of the material loading and unloading bins and the right or left feed direction.

LT3 550

Cutting belt with three upward conveyor blades, Ø 550 mm

The system, which is controlled by a fully numerical control, cuts the elements with a bar feeder and a saw with three blades set at 45 ° / 90 ° / 135 °, which provide a short cycle time for mass production. There are 8 different versions that can be configured according to the depth and length of the bins, the right / left feed direction and the type of cutting unit when loading / unloading material.

The system, which is controlled by a fully numerical control, cuts the elements with a bar feeder and a saw with three blades set at 45 ° / 90 ° / 135 °, which provide a short cycle time for mass production. There are 8 different versions that can be configured according to the depth and length of the bins, the right / left feed direction and the type of cutting unit when loading / unloading material.

LT 65

Cutting shank with front blade Ø 650 mm

The system, which is fully numerically controlled, cuts the elements with a bar feeder and a saw with a front blade exit. There are 20 different versions that can be configured according to the depth and length of the material loading and unloading bins and the right or left feed direction.

The system, which is fully numerically controlled, cuts the elements with a bar feeder and a saw with a front blade exit. There are 20 different versions that can be configured according to the depth and length of the material loading and unloading bins and the right or left feed direction.

LT 500

Cutting cord with front blade Ø 500 mm

The system, which is fully numerically controlled, cuts the elements with a bar feeder and a saw with a front blade exit. There are 4 different versions that can be configured according to the depth and length of the material loading / unloading bins, the right / left feed direction and the type of cutting unit.

The system, which is fully numerically controlled, cuts the elements with a bar feeder and a saw with a front blade exit. There are 4 different versions that can be configured according to the depth and length of the material loading / unloading bins, the right / left feed direction and the type of cutting unit.

LT 600

Cutting line with feeder blade upwards, Ø 600 mm, for 90 ° cutting

The system produces cut-to-size parts using a bar loading system and cutting machine with an upward-opening blade. 11 variants are available, which can be configured according to the depth and length of the material loading / unloading bins, the right / left feeding direction and the type of cutting unit.

The system produces cut-to-size parts using a bar loading system and cutting machine with an upward-opening blade. 11 variants are available, which can be configured according to the depth and length of the material loading / unloading bins, the right / left feeding direction and the type of cutting unit.