Cutting saws and rows

CUT 3B

CNC-controlled, 6-axis cutting center for high-productivity window and door frames (up to 500 single-leaf windows / 8h *).

LINEAR CUT 500

CNC cutting center with 3 controlled shafts for fast and optimal cutting of PVC profiles.

Built with the most innovative technology to perform all the necessary operations - loading a profile from the bar magazine, cutting and unloading the finished piece - in complete independence, without operator intervention

Built with the most innovative technology to perform all the necessary operations - loading a profile from the bar magazine, cutting and unloading the finished piece - in complete independence, without operator intervention

CUT 500

CNC cutting center with 1 or 2 controlled shafts according to the chosen configuration, designed to perform fast and optimal cutting of PVC profiles.

Compact and fast system built with the most innovative technology available on the market, designed to perform all the necessary operations - loading the profile from the bar, cutting and unloading the finished piece - in complete independence, the intervention of the operator.

Compact and fast system built with the most innovative technology available on the market, designed to perform all the necessary operations - loading the profile from the bar, cutting and unloading the finished piece - in complete independence, the intervention of the operator.

CUT V

CNC-controlled 4-axis cutting and machining center, specifically for those who want to automate the production of the Special Productions department.

The system consists of an automatic bar loader magazine that feeds the rising 1-blade cutting module through a grapple clamped by a linear motor, which guarantees cuts at extreme and middle angles.

The system consists of an automatic bar loader magazine that feeds the rising 1-blade cutting module through a grapple clamped by a linear motor, which guarantees cuts at extreme and middle angles.

FAB CUT PLASMA

An innovative cutting and working center that combines blade cutting with plasma technology designed to perform all the necessary work - gaps, holes and cut-outs - as well as cutting metal reinforcements.

The unique, intuitive and easy-to-use system is designed to significantly reduce execution time and features state-of-the-art production list management software that allows you to automatically import cut lists and synchronize production when you are online with Graf’s cutting and working centers. . Synergy.

The unique, intuitive and easy-to-use system is designed to significantly reduce execution time and features state-of-the-art production list management software that allows you to automatically import cut lists and synchronize production when you are online with Graf’s cutting and working centers. . Synergy.

FAB CUT 3BS

CNC-controlled, 12-axis cutting and machining center for window technology manufacturers that require high productivity (up to 250 single-leaf windows / 8 hours *).

This allows you to perform machining and cutting with very high precision and speed, while maintaining reliability and efficiency over time.

This allows you to perform machining and cutting with very high precision and speed, while maintaining reliability and efficiency over time.

FAB CUT 3B

CNC-controlled, 8-axis cutting and machining center for window manufacturers that require high productivity (up to 220 single-leaf windows / 8 hours *).

This allows you to perform machining and cutting with very high precision and speed, while maintaining reliability and efficiency over time.

This allows you to perform machining and cutting with very high precision and speed, while maintaining reliability and efficiency over time.

FAB CUT F1

5-6 axis CNC cutting and machining center that performs all machining and cutting in an optimized way on PVC profiles.

Compact and versatile system built with the most innovative technology available on the market, which guarantees extremely high reliability and accuracy over time

Compact and versatile system built with the most innovative technology available on the market, which guarantees extremely high reliability and accuracy over time

FAB CUT V

CNC-controlled, 6-axis cutting and machining center, specifically for those who want to automate the production of the Special Productions department.

The system consists of an automatic bar loader magazine that feeds the machining module through a linear motor-clamped grab that can accommodate up to 12 high-speed spindles (6 standards) and an ascending 1-blade cutting module that guarantees cuts at extreme and center angles.

The system consists of an automatic bar loader magazine that feeds the machining module through a linear motor-clamped grab that can accommodate up to 12 high-speed spindles (6 standards) and an ascending 1-blade cutting module that guarantees cuts at extreme and center angles.

LINEAR FAB 5000

CNC machining center with 5 controlled axes for machining any cutting profile with pre-installed reinforcement.

The system consists of an automatic magazine for loading cut profiles, which feeds the multi-spindle machining module with PVC and / or metal reinforcement tools via a linear motor-operated CNC grab, which guarantees machining of the profile on both sides of the profile, including those prone to

The system consists of an automatic magazine for loading cut profiles, which feeds the multi-spindle machining module with PVC and / or metal reinforcement tools via a linear motor-operated CNC grab, which guarantees machining of the profile on both sides of the profile, including those prone to

RMA

A machine of its kind, the RMA is equipped with a modern anthropomorphic arm that selects the right striker based on the profile it should operate and places it exactly where a screwdriver secures it to the frame.

The system allows significant savings in execution time and cost as it does not require work, so the operator is free to leave other activities while the machine independently fixes the strikers to the profile.

The system allows significant savings in execution time and cost as it does not require work, so the operator is free to leave other activities while the machine independently fixes the strikers to the profile.

ASG-E

It is a unique machine of its kind, it works on PVC profiles, with the already installed metal reinforcement.

It is a CNC system which, thanks to a fastening module capable of accommodating up to 3 screwdrivers (1 standard) and various tools with independent movement, allows various processes to be performed - screwing the reinforcement, holes for wall mounting, transverse holes and their triple handle weight - in an extremely precise and accurate manner.

It is a CNC system which, thanks to a fastening module capable of accommodating up to 3 screwdrivers (1 standard) and various tools with independent movement, allows various processes to be performed - screwing the reinforcement, holes for wall mounting, transverse holes and their triple handle weight - in an extremely precise and accurate manner.

FAZ RS

The desktop is designed and built to automatically assemble and screw in hardware on Pvc window frames.

Prepared for insertion into an automated production line, it consists of 2 stations: a preparation table showing the components to be assembled and marking the compartment in which they are located, and an automatic screwdriving table where the hardware is fixed on all four sides of the sash thanks to a portal with 2 screwdrivers .

Prepared for insertion into an automated production line, it consists of 2 stations: a preparation table showing the components to be assembled and marking the compartment in which they are located, and an automatic screwdriving table where the hardware is fixed on all four sides of the sash thanks to a portal with 2 screwdrivers .

FAZ II

Bench designed and built to assemble and bolt the hardware to PVC window frames in an automated manner.

The unit consists of 2 stations: the preparation table and the screwing table: in the first the panel is pre-assembled (cutting and positioning the hardware), which is then automatically transported to the second, where 2 pneumatic screws secure the hardware; the operator can start pre-assembling the next wing at the same time.

The unit consists of 2 stations: the preparation table and the screwing table: in the first the panel is pre-assembled (cutting and positioning the hardware), which is then automatically transported to the second, where 2 pneumatic screws secure the hardware; the operator can start pre-assembling the next wing at the same time.

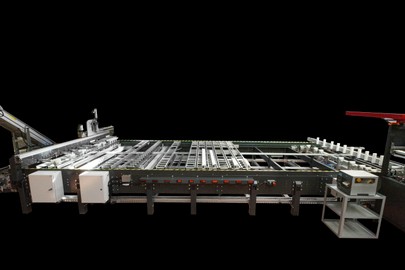

DYNAMIC TABLE

Modular connection system adaptable to different types of profiles, equipped with self-moving bowls that move each rod; this allows the spaces to be optimized due to the constant flow to the screw center when each bowl from which the dynamic unit is made is filled only when it is full.

It is configurable to connect the machines to both U and Z positions.

It is configurable to connect the machines to both U and Z positions.