Auxiliary equipment

WP CNC 2

A 2-axis, linear motor-driven corner cleaning machine that automatically performs all operations related to the external cleaning of the welding edge of PVC profiles: centering, cleaning and release of the finished product.

We recommend the system as a stand-alone design and in combination with an automatic turntable; in this case, with a welding machine connected in a line 4 heads Quad.

We recommend the system as a stand-alone design and in combination with an automatic turntable; in this case, with a welding machine connected in a line 4 heads Quad.

WP OF4

Automatic cleaning machine with 4 milling units, which smooths welding rods and flat parts with pneumatically operated shaped knives.

The outer contours of the corner are cleaned by a milling system for this purpose.

The outer contours of the corner are cleaned by a milling system for this purpose.

WP CNC Turbo

CNC corner cleaning machine with 2 controlled shafts, brushless motors that automatically performs all operations related to the external cleaning of the welding beads of PVC profiles: centering, cleaning with special self-centering tools and release of the finished product.

The machine is also stand-alone and connected to an automatic piece player; in this case, it can be aligned with a four-headed Quad welder

The machine is also stand-alone and connected to an automatic piece player; in this case, it can be aligned with a four-headed Quad welder

F 16

Automatic table for drilling PVC frame frames of any size.

The holes made after welding are determined by the internal reference obtained by automatically measuring the distance of the glass bead.

The holes made after welding are determined by the internal reference obtained by automatically measuring the distance of the glass bead.

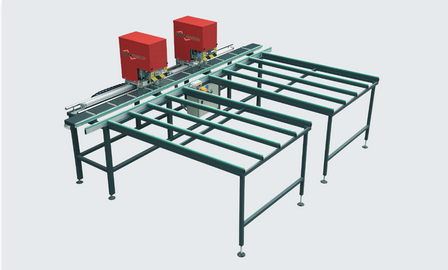

BM AS CNC

Automated system for drilling and assembling hinges and assembling PVC solar systems; ideal for drilling pieces up to 1,200 x 2,400 mm.

Equipped with an electrically welded steel structure and a leveling base, it is a versatile multifunctional table consisting of 2 independent, hand-operated tables with scratch-resistant and low-friction surfaces that make the window easier to slide and minimize operator effort.

Equipped with an electrically welded steel structure and a leveling base, it is a versatile multifunctional table consisting of 2 independent, hand-operated tables with scratch-resistant and low-friction surfaces that make the window easier to slide and minimize operator effort.

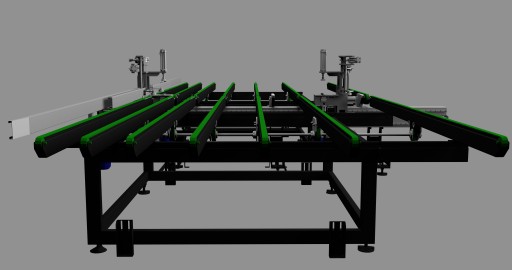

AHM

CNC table with 3 controlled shafts designed and built for drilling and assembling hinges.

Equipped with a solid welded steel structure, it is an ideal solution for insertion into an automated production line.

The table is equipped with a motorized loading roller conveyor and multiple heads that move on a portal with a controlled shaft that performs all the necessary steps: drilling, assembling and screwing the hinges.

Equipped with a solid welded steel structure, it is an ideal solution for insertion into an automated production line.

The table is equipped with a motorized loading roller conveyor and multiple heads that move on a portal with a controlled shaft that performs all the necessary steps: drilling, assembling and screwing the hinges.

HDHS

A drilling rig designed to automatically drill holes in a wing joint.

The table is equipped with four - two horizontal and two vertical - pneumatic clamps for a safe and precise block and a two-way drill bit with mechanical positioning; the holes are on the reference to the outer edge of the door.

The table is equipped with four - two horizontal and two vertical - pneumatic clamps for a safe and precise block and a two-way drill bit with mechanical positioning; the holes are on the reference to the outer edge of the door.

HDH

CNC drilling table with 3 controlled shafts designed to automatically drill hinge holes in the frames.

HDH provides the perfect PVC drilling cycle, controlled by an automatic drilling depth controller and equipped with an automatic reset sequence at the end of processing.

HDH provides the perfect PVC drilling cycle, controlled by an automatic drilling depth controller and equipped with an automatic reset sequence at the end of processing.

BFB 1000 S

Multifunctional table for complete assembly of perimeter hardware for PVC, wood-aluminum and aluminum frames.

Equipped with a solid steel structure, leveling feet and a large anti-scratch worktop with welded rods, the BFB 1000 S is the ideal solution for faster and easier hardware assembly, handle bore and hinge design holes.

Equipped with a solid steel structure, leveling feet and a large anti-scratch worktop with welded rods, the BFB 1000 S is the ideal solution for faster and easier hardware assembly, handle bore and hinge design holes.

RP E S& DX-300

A roller conveyor is equipped with a moving stop driven by an electric motor with electronic positioning that determines the length of the profile to be cut.

Equipped with a large 17 "screen and an independent PC with dedicated software, it offers easy operation and a wide range of functions.

Equipped with a large 17 "screen and an independent PC with dedicated software, it offers easy operation and a wide range of functions.

RP BM

Unloading of the side roller conveyor with a movable stop with a manual sliding position on the guide and position reading on a millimeter scale.

Made of solid steel, welded and height-adjustable with legs, made of solid construction, with horizontal and vertical PVC rollers to facilitate sliding of cut pieces, and particularly suitable for pieces to be cut with a hand miter saw (plugs or profiles).

Made of solid steel, welded and height-adjustable with legs, made of solid construction, with horizontal and vertical PVC rollers to facilitate sliding of cut pieces, and particularly suitable for pieces to be cut with a hand miter saw (plugs or profiles).

RP S

A load-side roller conveyor is made with a solid electro-welded steel structure to support the profile to be cut, and with dowel supports and height-adjustable legs.

Equipped with both horizontal and vertical PVC rollers to facilitate sliding of the pieces, it is particularly suitable for supporting and moving rods to be loaded with a hand miter saw (glazing or profiles).

Equipped with both horizontal and vertical PVC rollers to facilitate sliding of the pieces, it is particularly suitable for supporting and moving rods to be loaded with a hand miter saw (glazing or profiles).

RP E S9

The side roller conveyor is equipped with a movable stop driven by an electric cutting electric motor that determines the length of the profile to be cut.

Display dimensions, images and messages on a 6-inch, high-brightness graphic display.

Display dimensions, images and messages on a 6-inch, high-brightness graphic display.

SE 1

Screw unit for reinforcement can be controlled by manual positioning of the piece, automatic self-drilling screw dosing system and pedal button.

SE 1 is an extremely solid and reliable structure, it is a vertical pneumatic system without electrical slavery, which is recommended with a welded plate ground support, a roller conveyor for fixing both sides of the profile and a horizontal pneumatic fixing device.

SE 1 is an extremely solid and reliable structure, it is a vertical pneumatic system without electrical slavery, which is recommended with a welded plate ground support, a roller conveyor for fixing both sides of the profile and a horizontal pneumatic fixing device.

F 126

Manual or hydraulic control machine with single horizontal axis i ndispensable for grinding the crossmembers and vertical PVC.

The machine is equipped with horizontal and vertical pneumatic clamps to block the workpiece, out-of-square tool -45 ° Right or + 45 ° Left and an efficient tool cooling system.

The machine is equipped with horizontal and vertical pneumatic clamps to block the workpiece, out-of-square tool -45 ° Right or + 45 ° Left and an efficient tool cooling system.

TEST PRO DIGITAL

A machine designed to control the measurement of the compressive load tolerant of welded PVC corners; the tightness of the seams made during the manufacture of doors and windows must be checked.

Built with a solid carbon steel structure, Test Pro Digital is a lightweight machine with a certified measuring cell system and is essential for any PVC window company.

Built with a solid carbon steel structure, Test Pro Digital is a lightweight machine with a certified measuring cell system and is essential for any PVC window company.

RF330 GS

Horizontal jigsaw for cutting PVC window frames.

The work in progress rests on a large work surface covered with anti-friction and scratch-resistant strips, which ensures easy maneuvering and easy handling of the pieces.

The work in progress rests on a large work surface covered with anti-friction and scratch-resistant strips, which ensures easy maneuvering and easy handling of the pieces.